Hey there! If you’re a manufacturing company looking to streamline your operations and boost efficiency, implementing an ERP (Enterprise Resource Planning) system could be the game-changer you’ve been searching for. From optimizing production processes to enhancing inventory management, an ERP system can provide a wide range of benefits that can help your company stay ahead of the competition. Let’s dive into the advantages of integrating an ERP system into your manufacturing operations.

Benefits of implementing an ERP system in a manufacturing company

Implementing an Enterprise Resource Planning (ERP) system in a manufacturing company can bring about a multitude of benefits that can streamline processes, increase efficiency, and ultimately lead to improved profitability. One of the main advantages of implementing an ERP system is improved visibility and transparency across the entire organization. By consolidating all business functions into one integrated system, managers and decision-makers have real-time access to key data and metrics that can help them make informed decisions. This increased visibility can lead to better forecasting, production planning, and inventory management, ultimately reducing costs and minimizing waste.

Another key benefit of implementing an ERP system in a manufacturing company is increased productivity. With all departments working off of the same system and having access to the same data, tasks can be completed more quickly and with fewer errors. Automation of routine tasks and workflows can also help employees focus on more value-added activities, leading to improved overall efficiency. Additionally, an ERP system can help streamline communication between different departments, reducing silos and promoting collaboration.

Cost savings is another significant benefit of implementing an ERP system in a manufacturing company. By streamlining processes, reducing manual data entry, and improving inventory management, companies can cut costs associated with excess inventory, production delays, and inefficiencies. Better visibility into the supply chain and production processes can also help identify areas where costs can be reduced or processes can be optimized, leading to overall cost savings.

Furthermore, implementing an ERP system can improve customer satisfaction and ultimately drive increased sales. With better inventory management and production planning, companies can ensure timely delivery of products to customers, reduce lead times, and improve quality control. This can result in happier customers, repeat business, and positive word-of-mouth referrals.

Lastly, implementing an ERP system can help manufacturing companies stay competitive in a rapidly changing market. With the ability to adapt quickly to changing customer demands, market trends, and regulatory requirements, companies can maintain their competitive edge and continue to grow and innovate. By leveraging real-time data and analytics, companies can make data-driven decisions that help them stay ahead of the competition.

In conclusion, the benefits of implementing an ERP system in a manufacturing company are numerous and can have a significant impact on the overall success and profitability of the organization. From improved visibility and productivity to cost savings and increased customer satisfaction, an ERP system can help companies optimize their operations and drive growth in a competitive market.

Key features to look for in an ERP system for a manufacturing company

Implementing an Enterprise Resource Planning (ERP) system is essential for any manufacturing company looking to streamline its operations, improve efficiency, and stay competitive in today’s fast-paced market. However, with so many options available, it can be overwhelming to choose the right ERP system for your specific needs. Here are some key features to look for when selecting an ERP system for your manufacturing company:

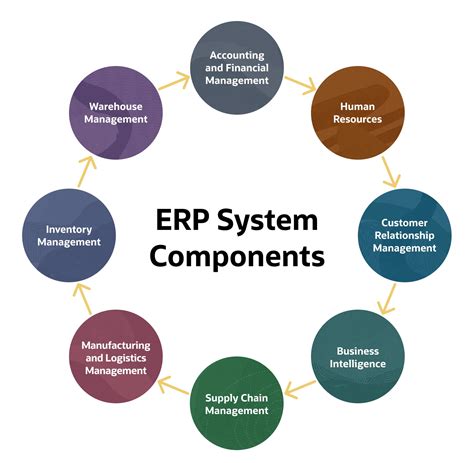

1. Integration capabilities: One of the most important features to consider in an ERP system for a manufacturing company is its ability to integrate with other systems and processes within the organization. A good ERP system should be able to seamlessly connect with your existing software, such as inventory management, production planning, and customer relationship management systems. This integration not only helps in data sharing and visibility across departments but also eliminates the need for manual data entry, reducing the risk of errors and improving overall efficiency.

2. Advanced inventory management: A robust inventory management module is crucial for manufacturing companies that deal with complex supply chains and large volumes of raw materials and finished goods. Look for an ERP system that offers features such as real-time inventory tracking, automated reorder points, lot tracking, and serial number management. Additionally, a good ERP system should provide tools for demand forecasting, allowing you to optimize inventory levels, reduce carrying costs, and minimize stockouts.

3. Production planning and scheduling: Efficient production planning and scheduling are vital for meeting customer demands while minimizing production costs and lead times. When choosing an ERP system for your manufacturing company, look for features such as capacity planning, routing optimization, resource allocation, and machine downtime tracking. These functionalities help in creating accurate production schedules, improving production efficiency, and maximizing machine utilization.

4. Quality control and compliance: Maintaining high-quality standards and complying with industry regulations are non-negotiable for manufacturing companies. An ERP system with built-in quality control tools can help in automating quality inspections, tracking defects, and ensuring compliance with standards such as ISO and FDA. Look for features such as statistical process control, non-conformance management, and document control to effectively manage quality processes and certifications.

5. Business intelligence and analytics: In today’s data-driven world, having access to real-time insights and analytics is essential for making informed business decisions. A good ERP system should provide advanced reporting tools, dashboards, and data visualization capabilities to help you monitor key performance indicators, track trends, and identify areas for improvement. Additionally, look for predictive analytics features that can help you forecast demand, optimize production processes, and identify cost-saving opportunities.

Choosing the right ERP system for your manufacturing company is a critical decision that can have a significant impact on your business’s success. By considering these key features and conducting thorough research, you can select an ERP system that meets your specific requirements and helps you achieve your operational goals.

How an ERP system can improve efficiency in a manufacturing company

Implementing an ERP system in a manufacturing company can bring numerous benefits, especially when it comes to improving efficiency. Here are some ways in which an ERP system can help enhance efficiency:

1. Streamlining Processes: An ERP system integrates various departments and functions within a manufacturing company, allowing for better coordination and communication between different teams. This streamlined approach eliminates the need for manual data entry and reduces the chances of errors, ultimately saving time and improving overall efficiency.

2. Real-time Data Access: One of the key features of an ERP system is its ability to provide real-time data access to all employees. This means that everyone in the company can access the most up-to-date information about inventory levels, production schedules, and customer orders. With this information at their fingertips, employees can make informed decisions quickly, leading to increased productivity and efficiency.

3. Inventory Management: ERP systems come equipped with advanced inventory management functionalities that allow manufacturers to optimize their inventory levels. By accurately tracking raw materials, work-in-progress, and finished goods, companies can avoid overstocking or stockouts, leading to cost savings and improved production efficiency. Additionally, ERP systems can automate tasks such as procurement and reorder point calculations, eliminating manual errors and reducing the time spent on inventory management tasks.

4. Production Planning and Scheduling: ERP systems enable manufacturers to create detailed production plans and schedules based on real-time demand and resource availability. This allows companies to optimize their production processes, identify bottlenecks, and make adjustments as needed to meet customer requirements. With the help of an ERP system, manufacturing companies can reduce lead times, improve on-time delivery rates, and enhance overall operational efficiency.

5. Quality Control: Maintaining high-quality standards is crucial for manufacturing companies to ensure customer satisfaction and regulatory compliance. An ERP system can help companies implement quality control processes by tracking production metrics, monitoring product defects, and identifying areas for process improvement. By implementing automated quality control procedures, manufacturers can reduce rework, minimize waste, and increase production efficiency.

Overall, an ERP system plays a vital role in improving efficiency in a manufacturing company by streamlining processes, providing real-time data access, optimizing inventory management, facilitating production planning and scheduling, and enhancing quality control measures. By leveraging the capabilities of an ERP system, manufacturing companies can increase productivity, reduce costs, and stay competitive in today’s fast-paced business environment.

Case studies of successful ERP implementations in manufacturing companies

Implementing an ERP system in a manufacturing company can be a game-changer, streamlining processes, improving efficiency, and increasing overall productivity. Here are a few case studies of successful ERP implementations in manufacturing companies:

Case Study 1: Company XYZ, a leading automobile manufacturer, implemented an ERP system to streamline their supply chain management and production processes. By integrating their inventory, sales, and production data into one system, they were able to reduce lead times, optimize inventory levels, and improve customer satisfaction. The ERP system also provided real-time visibility into their operations, allowing them to make informed decisions quickly.

Case Study 2: Manufacturer ABC, a global electronics company, implemented an ERP system to improve their quality control processes and reduce costs. By tracking every step of the production process in real-time, they were able to identify bottlenecks, streamline workflows, and detect defects early on. This led to a significant decrease in product recalls and an increase in customer satisfaction.

Case Study 3: Industrial Company LMN, a heavy machinery manufacturer, implemented an ERP system to manage their complex manufacturing processes more efficiently. By automating manual tasks such as scheduling and resource allocation, they were able to reduce production costs, improve on-time delivery, and increase overall operational efficiency. The ERP system also helped them track maintenance schedules and equipment performance, leading to a decrease in downtime and an increase in productivity.

Case Study 4: Manufacturer PQR, a textile company, implemented an ERP system to improve their forecasting accuracy and inventory management. By analyzing historical sales data and demand patterns, they were able to predict future demand more accurately, optimize inventory levels, and reduce stockouts. The ERP system also enabled them to collaborate more effectively with suppliers, resulting in shorter lead times and lower procurement costs.

These case studies demonstrate the significant impact that a successful ERP implementation can have on manufacturing companies. By leveraging the power of integrated data and streamlined processes, companies can achieve increased efficiency, reduced costs, improved customer satisfaction, and ultimately, a competitive advantage in the market.

Tips for selecting the right ERP system for your manufacturing company

Implementing an ERP system in a manufacturing company is a significant investment that can streamline operations and increase efficiency. However, with so many options available in the market, choosing the right ERP system can be a daunting task. Here are some tips to help you select the right ERP system for your manufacturing company:

1. Define your business requirements: Before you start evaluating ERP systems, it’s essential to have a clear understanding of your business requirements. Identify the key processes that need to be improved or automated, such as inventory management, production planning, or supply chain management. This will help you choose an ERP system that aligns with your specific needs.

2. Consider scalability: Your manufacturing company is likely to grow and evolve over time, so it’s crucial to choose an ERP system that can scale with your business. Look for a system that can accommodate additional users, features, and functionalities as your company expands.

3. Evaluate customization options: Every manufacturing company has unique processes and workflows. Choose an ERP system that offers customization options to tailor the system to your specific requirements. This will ensure that the ERP system can support your business processes effectively.

4. Assess integration capabilities: A manufacturing company typically uses multiple systems and tools to manage different aspects of the business, such as accounting software, CRM systems, or production tools. Choose an ERP system that can seamlessly integrate with your existing systems to avoid data silos and improve data accuracy.

5. Look for industry-specific features:

Choosing an ERP system that is specifically designed for the manufacturing industry can offer several benefits. Industry-specific ERP systems come with features and functionalities tailored to the unique needs of manufacturing companies, such as production scheduling, quality control, and compliance management. These features can help streamline operations and improve efficiency in your manufacturing company.

Additionally, industry-specific ERP systems are often developed by vendors with extensive experience in the manufacturing sector, ensuring that the system is robust and reliable. When evaluating ERP systems, look for industry-specific solutions that are proven to address the challenges faced by manufacturing companies.

6. Consider cloud vs. on-premise: Another crucial decision to make when selecting an ERP system is whether to opt for a cloud-based solution or an on-premise system. Cloud-based ERP systems offer flexibility, scalability, and lower upfront costs, making them an attractive option for many manufacturing companies. On the other hand, on-premise systems provide greater control over data security and customization. Consider your company’s specific needs and preferences before deciding on the deployment model.

By following these tips, you can select the right ERP system for your manufacturing company that meets your business requirements, scales with your growth, and improves operational efficiency.