Welcome to the world of manufacturing efficiency! In today’s fast-paced business environment, it’s essential for companies to streamline their operations and maximize productivity to stay competitive. One key tool that can help achieve these goals is an Enterprise Resource Planning (ERP) system. By integrating all aspects of a manufacturing business – from inventory management to production scheduling – an ERP system can significantly enhance efficiency and overall performance. Let’s explore how implementing an ERP system can revolutionize your manufacturing processes and propel your business to new heights.

Importance of ERP System in the Manufacturing Industry

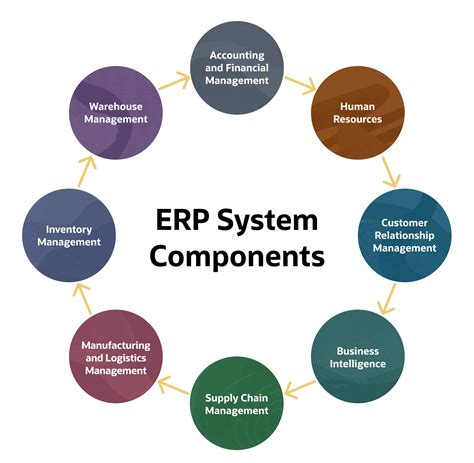

Enterprise Resource Planning (ERP) systems play a crucial role in the manufacturing industry by integrating all aspects of a company’s operations into a single unified system. In today’s fast-paced and highly competitive business environment, manufacturers need to streamline their processes, reduce costs, increase efficiency, and improve productivity in order to stay ahead of the competition. An ERP system helps manufacturers achieve these goals by providing them with real-time visibility into their operations, enabling better decision-making, and enhancing overall operational efficiency.

One of the key benefits of an ERP system in the manufacturing industry is improved productivity. By automating and streamlining manual processes, such as inventory management, production planning, and order processing, manufacturers can eliminate time-consuming tasks and reduce errors. This allows employees to focus on more value-added activities, which ultimately leads to increased productivity and higher output levels. In addition, an ERP system enables manufacturers to optimize their production schedules, allocate resources more effectively, and reduce lead times, all of which contribute to improved overall efficiency.

Another important benefit of an ERP system for manufacturers is enhanced decision-making. With real-time access to accurate and up-to-date data, managers can make informed decisions quickly and effectively. Whether it’s managing inventory levels, analyzing production costs, or forecasting demand, an ERP system provides the insights needed to make strategic decisions that drive business growth. Additionally, an ERP system can help manufacturers identify trends, spot opportunities for improvement, and anticipate challenges, allowing them to proactively address issues before they escalate.

Cost reduction is another significant advantage of implementing an ERP system in the manufacturing industry. By streamlining processes, reducing waste, and improving resource utilization, manufacturers can lower their operating costs and improve their bottom line. An ERP system can help identify inefficiencies in the production process, such as overproduction, excess inventory, or unnecessary downtime, and provide recommendations for improvement. By optimizing production processes and reducing waste, manufacturers can cut costs, increase profitability, and ultimately become more competitive in the market.

Furthermore, an ERP system can help manufacturers comply with industry regulations and standards, such as ISO certifications, FDA regulations, or environmental requirements. By tracking and documenting production processes, material usage, and quality control measures, manufacturers can ensure that they meet all necessary compliance standards and avoid costly penalties or fines. An ERP system can also help manufacturers maintain traceability and transparency throughout their supply chain, enabling them to track the origin of materials, monitor quality at each stage of production, and ensure product safety and integrity.

In conclusion, an ERP system is essential for manufacturers looking to streamline their operations, improve productivity, enhance decision-making, reduce costs, and ensure compliance with industry regulations. By providing real-time visibility, automation, and integration of all critical business processes, an ERP system empowers manufacturers to make informed decisions, optimize efficiency, and drive business growth. In today’s competitive manufacturing landscape, implementing an ERP system is no longer a luxury but a necessity for success.

Key Features of ERP Software for Manufacturing Companies

ERP software for manufacturing companies comes equipped with a range of features designed to streamline operations, improve efficiency, and enhance productivity. Here are some key features to look out for:

1. Inventory Management: One of the most important features of ERP software for manufacturing companies is its ability to manage inventory effectively. This includes tracking raw materials, finished goods, and work in progress, as well as optimizing inventory levels to prevent stockouts or excess inventory. ERP systems can also provide real-time visibility into inventory levels, enabling manufacturers to make informed decisions about purchasing and production.

2. Production Planning and Scheduling: Another crucial feature of ERP software for manufacturing companies is its production planning and scheduling capabilities. This includes creating and managing production schedules, optimizing production processes, and allocating resources efficiently. ERP systems can help manufacturers plan production based on factors such as demand forecasts, lead times, and capacity constraints, resulting in better production efficiency and reduced lead times.

3. Quality Control: ERP software for manufacturing companies often includes features for quality control to ensure that products meet customer requirements and industry standards. This can include tools for monitoring and analyzing quality metrics, managing non-conformances, and implementing corrective actions. Quality control functionality in ERP systems can help manufacturers identify and address quality issues in real-time, leading to improved product quality and customer satisfaction.

4. Supply Chain Management: Efficient supply chain management is critical for manufacturing companies, and ERP software can help streamline and optimize supply chain processes. This includes features for managing supplier relationships, forecasting demand, coordinating logistics, and tracking shipments. By integrating supply chain management functionality into their ERP systems, manufacturers can improve collaboration with suppliers, reduce lead times, and minimize supply chain risks.

5. Financial Management: In addition to operational features, ERP software for manufacturing companies also includes financial management capabilities to help manage financial processes such as accounting, budgeting, and financial reporting. This can include features for tracking costs, analyzing profitability, managing accounts receivable and payable, and generating financial statements. By integrating financial management functionality into their ERP systems, manufacturers can gain better visibility into their financial performance and make more informed financial decisions.

Overall, ERP software for manufacturing companies offers a wide range of features designed to address the unique challenges and requirements of the manufacturing industry. By leveraging these key features, manufacturers can improve efficiency, reduce costs, and enhance competitiveness in today’s fast-paced manufacturing environment.

Benefits of Implementing an ERP System in Manufacturing Processes

Implementing an Enterprise Resource Planning (ERP) system in the manufacturing industry can provide numerous benefits that streamline processes, improve efficiency, and enhance overall operations. Let’s delve into the key advantages of adopting an ERP system in manufacturing:

1. Enhanced Efficiency

One of the primary benefits of implementing an ERP system in a manufacturing setting is the enhanced efficiency it offers. ERP software integrates all aspects of the manufacturing process into one centralized system, allowing for seamless communication and collaboration between different departments. This streamlines processes, eliminates manual data entry errors, and reduces the time spent on repetitive administrative tasks.

2. Improved Data Accuracy

Another significant advantage of an ERP system is the improvement in data accuracy. By centralizing all data in one system, manufacturers can ensure that information is consistent across different departments and locations. This reduces the risk of data errors and inaccuracies, leading to better decision-making and more reliable reporting.

3. Better Inventory Management

Inventory management is a critical aspect of manufacturing operations, and an ERP system can greatly improve this process. With real-time visibility into inventory levels, manufacturers can better forecast demand, avoid stockouts, and optimize inventory holding costs. Additionally, ERP systems can automate the replenishment process, ensuring that materials are ordered at the right time and in the right quantities.

Furthermore, ERP systems can provide insights into inventory turnover rates, lead times, and supplier performance, allowing manufacturers to make data-driven decisions to improve overall inventory management practices.

In conclusion, implementing an ERP system in the manufacturing industry can deliver a wide range of benefits, from enhanced efficiency and improved data accuracy to better inventory management practices. By investing in an ERP system, manufacturers can streamline operations, reduce costs, and gain a competitive edge in today’s fast-paced market.

Challenges Faced in Implementing ERP Systems in the Manufacturing Sector

Implementing an ERP system in the manufacturing sector can be a complex and challenging process. There are several hurdles that organizations may face during the implementation phase, which can hinder the success of the project. Below are some of the common challenges faced in implementing ERP systems in the manufacturing industry:

1. Cost: One of the main challenges in implementing an ERP system in the manufacturing sector is the high cost associated with it. ERP systems can be expensive to purchase and implement, making it a significant investment for organizations. Additionally, there are ongoing costs such as maintenance, training, and customization that can further add to the financial burden.

2. Integration with existing systems: Another challenge in implementing ERP systems in the manufacturing sector is the integration with existing systems. Many manufacturers already have various systems in place for different functions such as inventory management, production planning, and supply chain management. Integrating these systems with the new ERP system can be a complex process, requiring careful planning and coordination.

3. Resistance to change: Resistance to change is a common challenge faced in implementing ERP systems in the manufacturing sector. Employees may be resistant to adopting new technology and processes, fearing that it may disrupt their daily routines or job roles. This resistance can hinder the successful implementation of the ERP system and affect its effectiveness in improving business processes.

4. Data migration and quality: One of the critical challenges in implementing ERP systems in the manufacturing sector is data migration and quality. Migrating data from existing systems to the new ERP system can be a time-consuming and complex process. Ensuring the accuracy and quality of the data is also crucial for the success of the ERP implementation. Inaccurate or incomplete data can lead to errors in reporting, decision-making, and overall system performance.

Organizations must carefully plan and execute data migration strategies to ensure that data is accurately transferred to the new ERP system. Data cleansing and validation processes should be implemented to improve data quality and integrity. Additionally, organizations can consider conducting data audits and training sessions to educate employees on the importance of data quality and the role they play in maintaining accurate and reliable data.

In conclusion, implementing an ERP system in the manufacturing sector can be a challenging endeavor. Organizations must address these challenges effectively to ensure the successful implementation and optimization of their ERP system. By identifying potential obstacles and developing strategies to overcome them, organizations can maximize the benefits of their ERP system and improve operational efficiency in the long run.

Best Practices for Selecting and Implementing ERP Solutions in Manufacturing Industry

Choosing the right ERP system for your manufacturing business is a crucial decision that requires careful consideration. With so many options available in the market, it can be overwhelming to select the best fit for your company. To help streamline this process, here are some best practices for selecting and implementing ERP solutions in the manufacturing industry.

1. Define your requirements: Before beginning your search for an ERP system, it is essential to clearly define your business requirements. Identify the specific functionalities and features that are critical for your manufacturing processes. This will help you narrow down your options and focus on solutions that align with your needs.

2. Conduct thorough research: Research is key to finding the right ERP solution for your manufacturing business. Take the time to explore different vendors, compare their offerings, and read customer reviews. Look for providers that have experience working with manufacturing companies and understand the unique challenges of the industry.

3. Consider scalability: As your manufacturing business grows, your ERP system should be able to keep up with the increasing demands. It is important to choose a solution that is scalable and can accommodate future growth. Make sure to discuss scalability options with potential vendors to ensure that the system can evolve with your business.

4. Involve key stakeholders: When selecting an ERP solution, it is crucial to involve key stakeholders from different departments within your organization. This includes employees from production, finance, IT, and other relevant areas. By including stakeholders in the decision-making process, you can ensure that the chosen ERP system meets the needs of all departments and facilitates seamless integration across the organization.

5. Plan for training and support: Once you have selected an ERP system, it is important to plan for training and ongoing support. Implementing a new system can be disruptive to your operations, so it is essential to provide comprehensive training to employees to ensure a smooth transition. Additionally, make sure to establish a support system with the ERP vendor to address any issues that may arise post-implementation.

In conclusion, selecting and implementing an ERP solution in the manufacturing industry requires careful planning and consideration. By following these best practices, you can streamline the selection process and ensure a successful implementation that meets the needs of your business. Remember to define your requirements, conduct thorough research, consider scalability, involve key stakeholders, and plan for training and support to set your manufacturing business up for success with a new ERP system.